Captivated by the mystery of Ukrainian knives, we plunged into this world with the desire to convey its beauty and strength. Our team not only creates knives, but also embodies in them the unique soul and identity of the Ukrainian people. Every knife, every name, every element of production is permeated with the deep roots of Ukrainian culture and history. We are proud to be able to bring this piece of our cultural heritage into the hearts of customers around the world. Against the background of modern challenges and needs, we feel responsible to contribute to the protection of our homeland.

Each of our knives has principles that guarantee its quality and reliability:

-

Quality and inspection of each element of the product;

-

Convenience of use even in extreme conditions;

-

Aesthetic design that will bring satisfaction to the owner.

Our process starts with choosing a concept, shape, and name. Each of our knives carries cultural and historical aspects of Ukraine, impressing both our compatriots and foreigners. Each knife has a name that carries something that glorifies Ukraine at the international level. Aeneas, Haydamak, Yarchuk, Tigrolov, Sirko, Khorunzhy and others … all these names tell Ukrainians and foreign owners what Ukraine is and how rich it is culturally and historically. You can read about each knife model in its characteristics.

We use X12MF steel (similar to D2, T30402), which guarantees excellent strength and durability. Our craftsmen control every stage of production, ensuring the high quality of each knife. Due to its characteristics, steel perfectly withstands transverse and lateral loads, and the cutting edge remains as sharp as possible. After years of testing, this steel is balanced between quality and price.

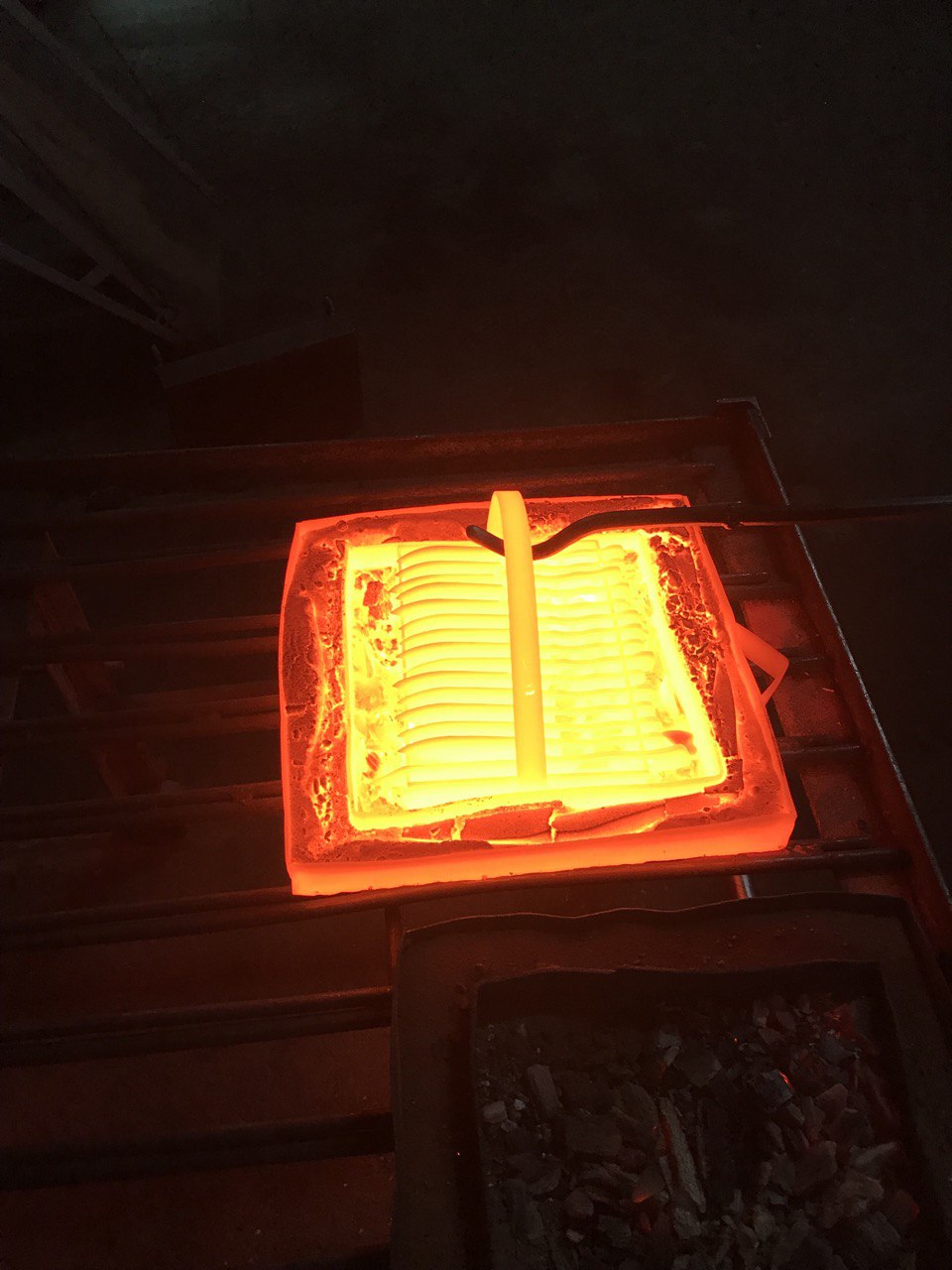

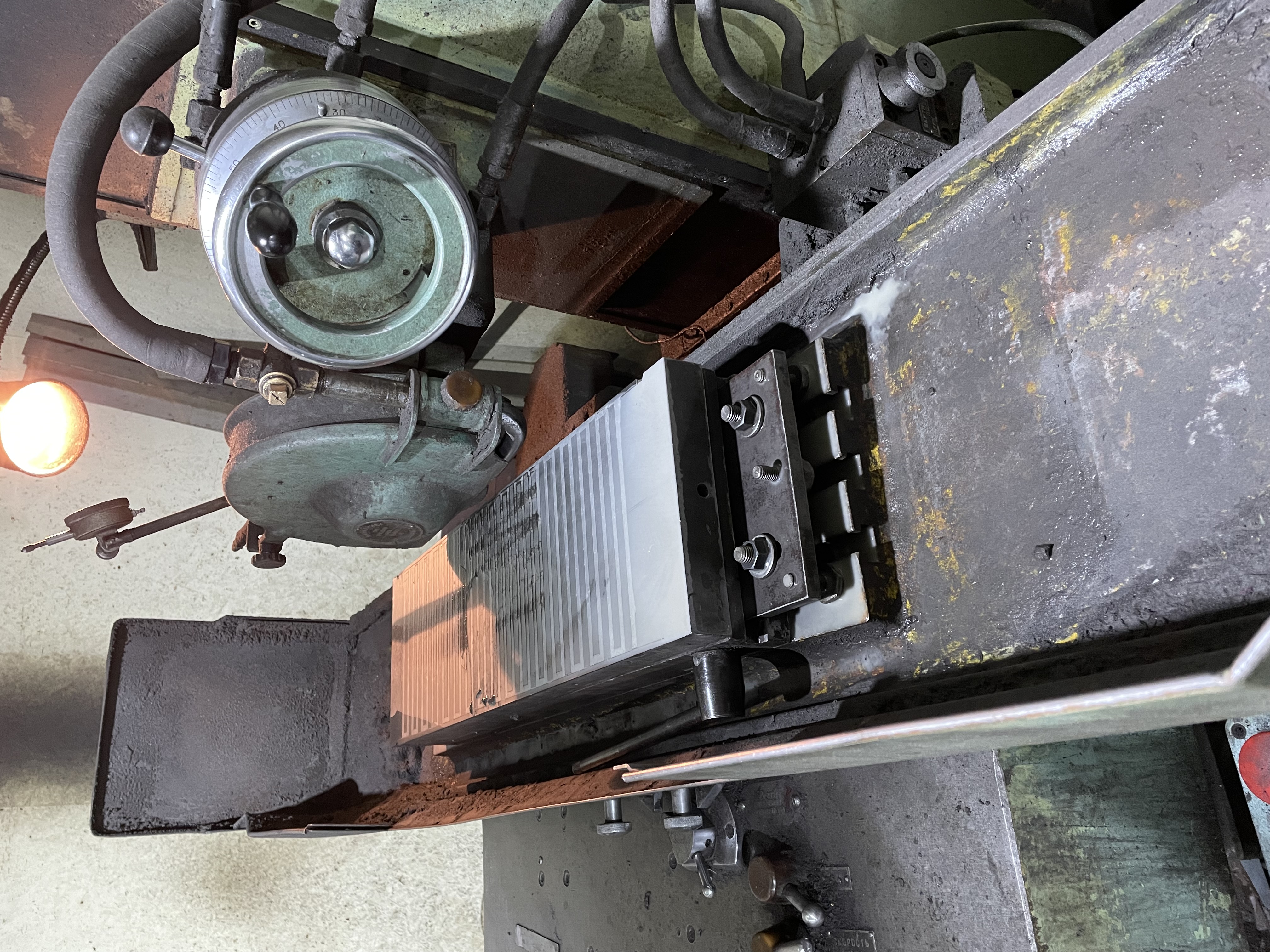

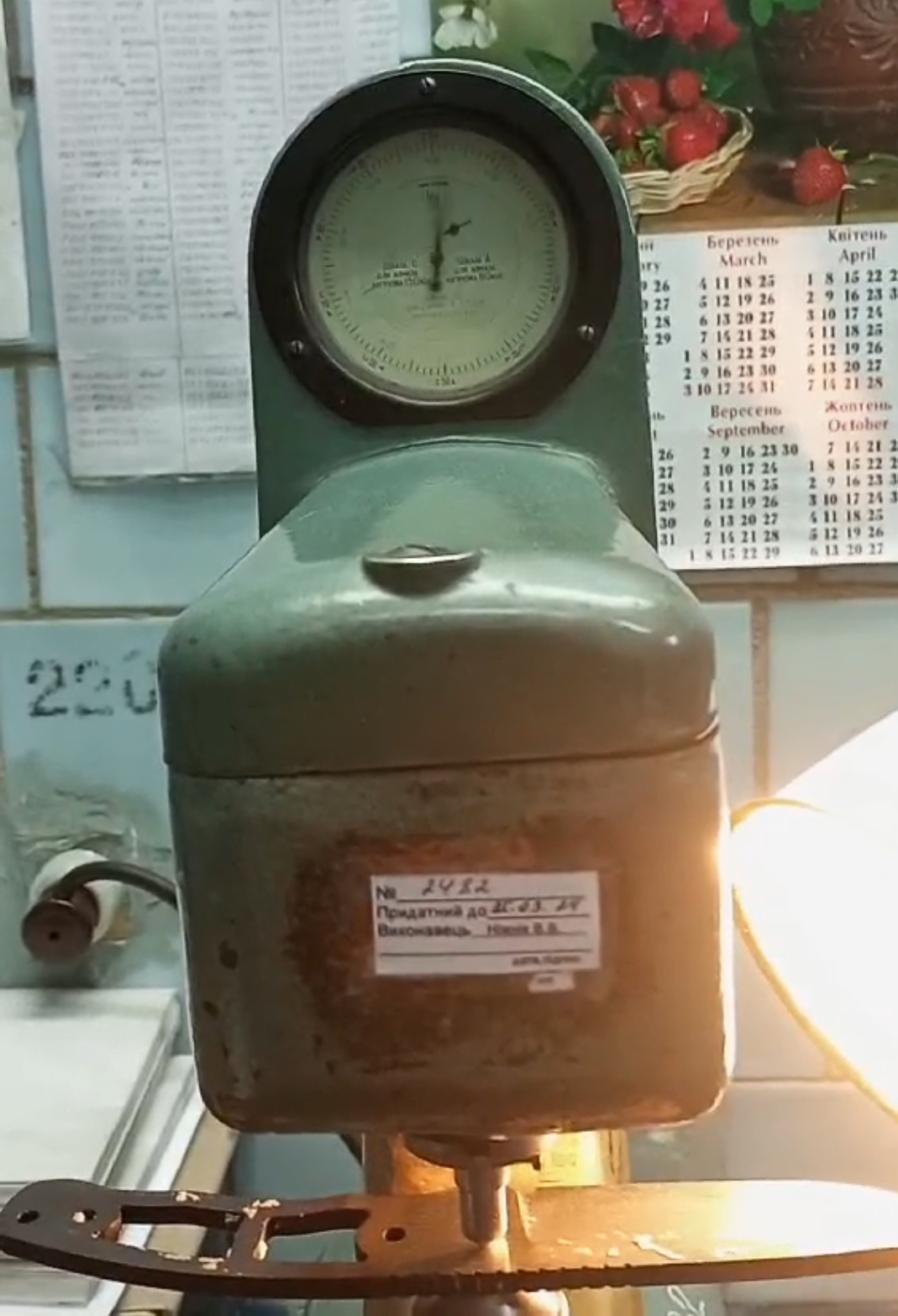

The heat treatment process is strictly controlled by our craftsmen. The entire batch is selectively checked on a stationary metal hardness tester according to the Rockwell system. Passing threshold from 57 to 58 units (see the product card for more details). After that, the workpieces are sent to a flat grinding machine, where we bring the workpiece to a micron level.

To protect metal, we use two types of coating: polymer coating and etching, providing maximum protection against external influences.

- Polymer coating: the knife first goes through the process of sandblasting (the carbon-free layer that forms after hardening is removed and at the same time the surface is perfectly prepared for subsequent dyeing), then it is dyed and baked in the oven. Titanium wheels are made in the same way, but we do not use varnish. The knife has permanent protection against moisture and various acids. But the engraving on it is not that good (in our opinion).

- Etching: the knife has protection against external irritants. Stonewash coating is the appearance of metal after hardening with hard elements. The knife has the appearance of small scratches. On this coating, the engraving looks very effective, because the metal is burned directly by the laser. This coating cannot be erased. We always use the best ferric chloride for etching.

We carefully control the quality of the coating of the workpiece, but we follow the rule: “A coating that does not rub off has not been invented yet”. You can always contact us to restore coverage or solve any problems. We are always in touch!

At grinding works we are energized by energetic music and charge each workpiece with positivity, because each workpiece is in the hands of the master behind the grinder from 1 to 2 hours ;)

The handle of a knife from prostaSTAL is like a fingerprint, it is unique and unrepeatable. We use mikart material for production. Micarta – one of the types of material that, along with wood and plastic, is most often used in the manufacture of knife handles and other cutting tools. Also, this material does not crack or rot, and is not yet susceptible to the destructive effects of bad weather. It is pleasant and warm in the hand. The handle is formed in the style of broken stone. Although, at first glance, it seems that it is chaotic, but we always keep the comfortable ergonomics of the handle, which gives hope and a strong grip. The color palette can be different, but for this you need to prepare the manufacturing process. Shade and color may vary depending on the batch.

Our hand sharpening, made using the most modern technologies, guarantees the highest quality and sharpness of each knife. Sharpening takes place with the help of a manual machine and with the use of 6 elbow blocks of different grain sizes. The standard sharpening angle is 40 degrees.

This angle is suitable for an aggressive cut, and at the same time we can change the sharpening angle at will. We are one of the few manufacturers that use manual sharpening instead of a sharpener. This is verified by our customers) Many marathons “I cut myself” can be seen on our Instagram page (link). With aggressive use, any knife can deteriorate its sharpening condition, for this you can always send it to us for resharpening - we will do it quickly and restore it.

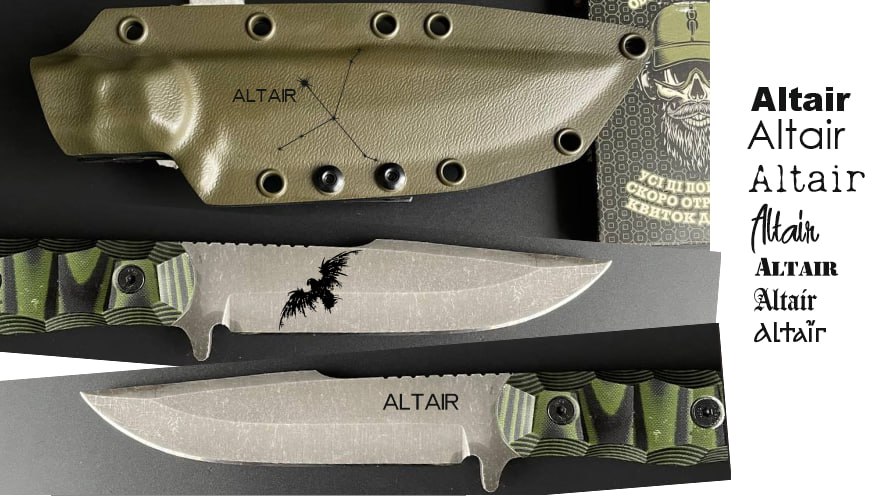

Our laser engraving — it is art and technological progress in one. Thanks to our own OCTA-fiber laser, we can create unique designs and inscriptions for you that will reflect your style and individuality.

The engraving process begins with creative design. Our designers work on creating a picture and choosing a font, ensuring the harmony and aesthetics of each element. We also take into account the specifics of knife manufacturing so that your design fits perfectly into the overall concept.

Once the layout is created, we consult with you to ensure it fully meets your requirements. After receiving your confirmation, we convert all designs into vector and apply them directly to metal or plastic using a laser.

Our laser engraving — it's not just drawing a picture on a surface, it's creating an unforgettable artistic masterpiece. We can realize any idea you have, from initials and symbols to complex graphics and relief carvings.

In addition, we offer engraving on bluing coatings, which not only looks stylish, but also has durability, as the design is fused into the metal. We can also design paired knives or create a scabbard design that will add uniqueness and individuality to your knife.

Trust us to create a unique image of your knife and make it truly special!

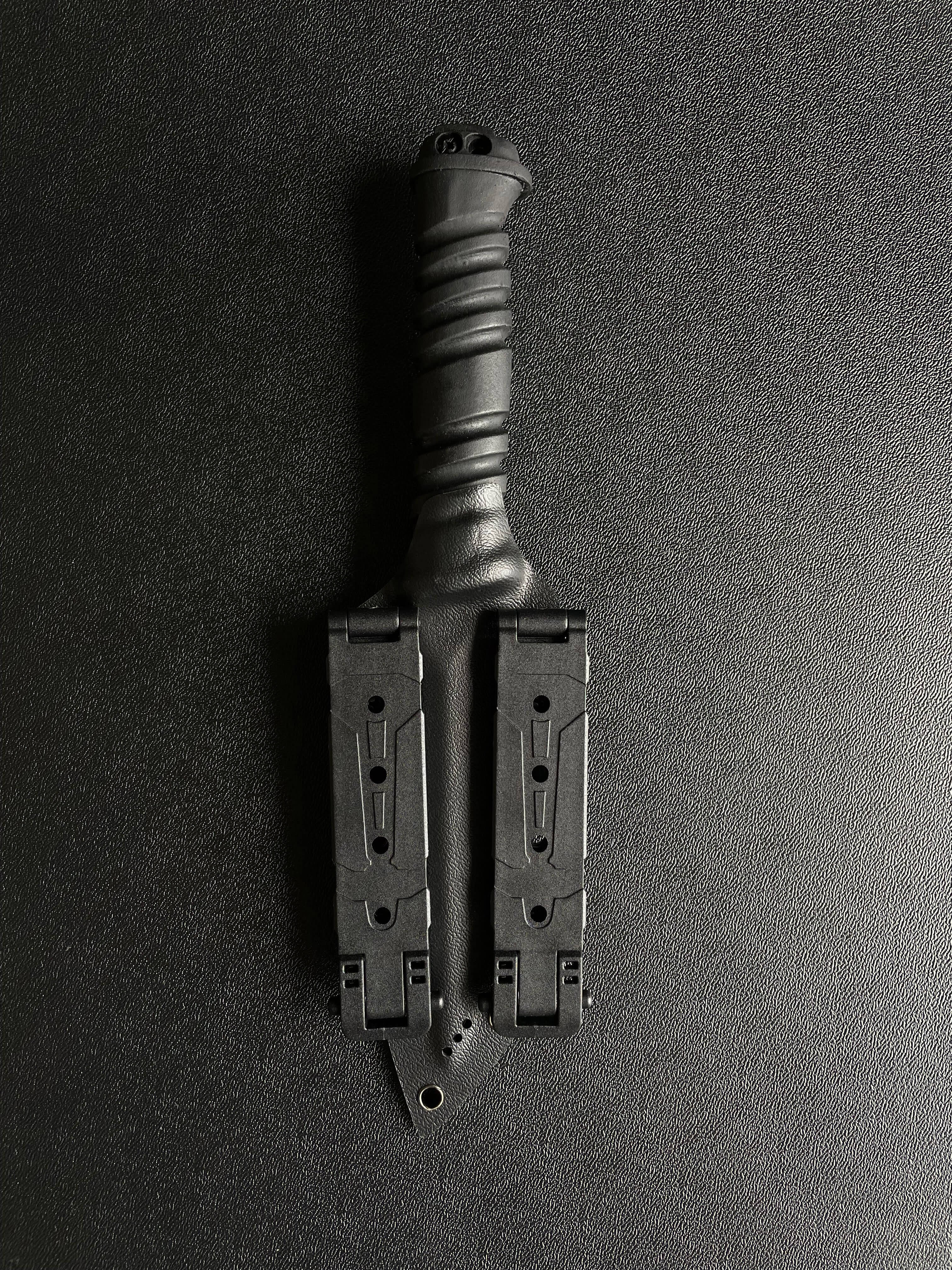

Our scabbards (covers, scabbards) — it is the epitome of your style and convenience. Each sheath is handcrafted to the highest quality standards, ensuring maximum comfort and reliability in carrying your knife.

We carefully study your wishes and needs, guaranteeing an individual approach to each client. You can choose sheath knife seat density, color, engraving, and mounts from our largest selection on the market. We also take into account your preferred carrying angle and make it for left- or right-handed use.

Using our sheaths, you get:

-

Maximum comfort and convenience in carrying a knife.

-

A wide selection of colors and engravings for individual style.

-

Reliable fastening with the largest selection on the market.

-

Manufacturing for left-handed or right-handed people.

-

Using the best materials such as Kydex, Boltaron, Holstex and ABS plastic to ensure durability and quality.

We also specialize in manufacturing sheaths (covers, scabbards) for all popular knife brands, including Glock, Kabar, Benchmade, Spyderco, Cold Steel, CRKT, Gerber, Ontario Knife Company, Buck Knives, SOG Knives, Case Knives, Kershaw, Victorinox, Zero Tolerance, Leatherman, Boker, Emerson Knives, TOPS Knives, Helle, Morakniv and many more. Regardless of your knife model, we guarantee you a perfectly fitting and functional sheath.

A tourist or skeleton knife from prostaSTAL is a knife with a soul, history, and a piece of Ukrainian culture.